Microwave technology in process optimization pdf

School of Chemical Sciences and Food Technology, Faculty of Science and Technology, Universiti Kebangsaan Malaysia, 43600 UKM, Bangi, Selangor, Malaysia Optimization studies on microwave assisted extraction of dragon fruit (Hylocereus polyrhizus) peel pectin using response surface methodology Abstract Optimization of microwave assisted extraction of dragon fruit peel pectin …

Li, Nanya, Li, Yingguang, Hang, Xiang and Gao, James (2014) Analysis and optimization of temperature distribution in carbon fiber reinforced composite materials during microwave curing process. Journal of Materials Processing Technology, 214 (3). pp. 544-550.

11/03/2013 · Gerhard Brandt, ABB AG, Mannheim, Germany. Solutions for Performance Monitoring, Diagnosis and Optimization of Power Plants Agenda Introduction

the further optimization process (Siala et al., 2012). For example Siala et al. (2012) used a Plackett– For example Siala et al. (2012) used a Plackett– Burman design to analyse the effect of various conditions related to the composition of the medium,

The design of an UWB receiver would require optimization of microwave parameters like scattering figures (s-parameters), noise (NF min and NF), small signal forward gain, measure of linear range, and power expenditure.

transesterification process to obtain a high conversion to biodiesel. Response surface methodology (RSM) Response surface methodology (RSM) was used to analyze and to optimize the operating parameters of that process.

Analysis and Optimization of Solvent Free Microwave Assisted Extraction of Bio-oil from Orange peels using Response Surface Methodology Pawan D. Meshram*, Amol J. Gore & Ghayas A. Usmani Department of Oil Technology University Institute of Chemical Technology, North Maharashtra University Jalgaon, Maharashtra 425 001, India E-mail: pawan.dm@gmail.com Abstract – In present …

Optimization of Microwave Assisted Extraction of Pectin from Orange Peel Using Response Surface Methodology Microwave assisted extraction of pectin from dried orange peel powder was carried out in a microwave oven with acidified water using concentrated nitric acid. Process parameters like pH of the acidified water (1.5, 2, 2.5), solvent: solid ratio (10, 20, 30), microwave power (360, 540

IEEE TRANSACTIONS ON MICROWAVE THEORY AND TECHNIQUES 1-Band Total Power Radiometer Performance Optimization in an SiGe HBT Technology E. Dacquay, Student Member, IEEE, A. Tomkins, K. H. K. Yau, Member, IEEE, E. Laskin, Pascal Chevalier, Member, IEEE, A. Chantre, Senior Member, IEEE, B. Sautreuil, and S. P. Voinigescu, Senior Member, IEEE …

The results showed that the extraction time is the most prominent factor followed by microwave power level and sample type for extraction process. An average of 0.25% of ginger oil can be extracted using current setup. The optimum conditions for the ginger oil extraction using SFME were the extraction time 30 minutes, microwave power level 640 watts, and sample type, crushed sample. Solvent

For Bioenergy Process Optimization, and Green Energy Efficiency . Scott Reed, Black & Veatch, Inc. Peter Brady, Alpine Technology, Inc. ABSTRACT . Between 1997 and 2002, there were two significant dewatering automation development projects; one by WERF, and the other by STOWA in the Netherlands (STOWA is the equivalent of a combined WERF and AwwaRF). The purpose of these …

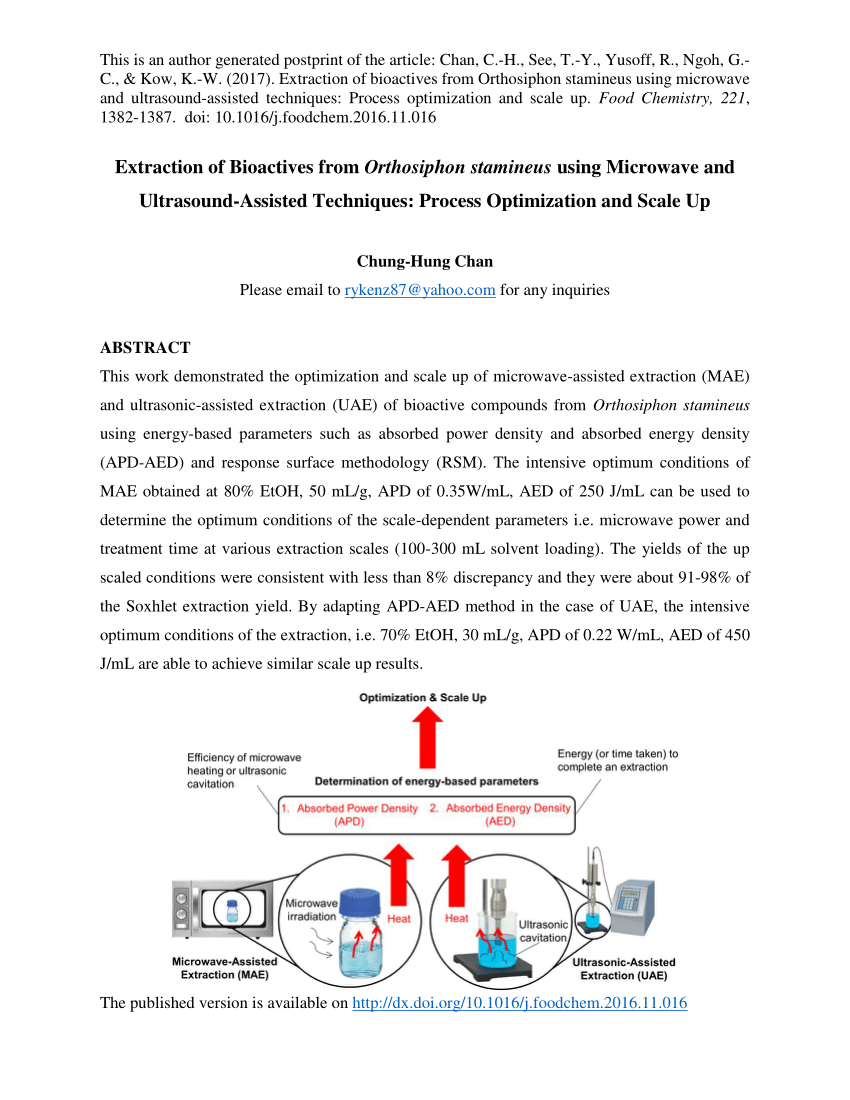

Abstract. This work demonstrated the optimization and scale up of microwave-assisted extraction (MAE) and ultrasonic-assisted extraction (UAE) of bioactive compounds from Orthosiphon stamineus using energy-based parameters such as absorbed power density and absorbed energy density (APD-AED) and response surface methodology (RSM).

Optimization of Process Parameters for Convective-cum

Microwave assisted biodiesel production from DeepDyve

Chemical Process Engineering Journals Is a branch of engineering that applies physical sciences and life sciences practicing researchers in industry and academia, working in the field of Process Engineering Journals and related to the subject of Process Intensification. together with mathematics and economics to produce, transform, transport

Process Optimization for Injection Moulding of Passive Microwave Components. In Proceedings of the 11th In Proceedings of the 11th International Conference on Multi-Material Micro Manufacture (4M2016) : co-organised with 10th International

CONFERENCE PROCEEDINGS Papers Presentations Journals. Advanced Photonics Journal of Applied Remote Sensing

critical component in the design and optimization process of a power amplifier (PA). Through the use of load-pull the device can be subjected to the impedance environments required for the design and optimization of PAs. The procedures such as load-pull, also called load tuning mechanism, characterizations are extensively conducted on transistor devices for the determination of optimum

The objectives of this study were to investigate the effect of drying parameters (microwave power, air temperature and speed) on the quality of dried okra and to optimize the drying conditions based on quality of dried product and specific energy consumption during process.

16 Anup Kumar Das, Vivekananda Mandal, Subhash C. Mandal, A Brief Understanding of Process Optimisation in Microwave-assisted Extraction of Botanical Materials: Options and Opportunities with Chemometric Tools, Phytochemical Analysis, 2014, 25, 1, 1Wiley Online Library

The effi ciency of a microwave-assisted Fenton-like process using special supported catalysts was evaluated using total organic carbon (TOC) removal from pharmaceutical wastewater. No acidifi cation was required. The highest level of TOC removal effi ciency from wastewater achieved was 65.88%. Moreover, the maximum number of consecutive uses with high activity was four. Under optimal

The changes in the characteristics of plaster of Paris (pop) during drying operation under microwave irradiation conditions, namely surface morphology, effective moisture diffusivity, and absorption of microwave, were studied. The drying characteristics and kinetics of the process during microwave

Lorentzen & Wettre Products Process Optimization L&W Moisture Tester is the ultimate offline moisture measurement solution for paper, paperboard, corrugated board, dry pulp, and other fibre materials. It measures moisture content at all stages of the process chain. And thanks to the quick measurement procedure, it can also be used for product checking when online moisture sensors …

In this paper, statistical analysis and process conditions optimization of Iranian heavy crude oil upgrading has been conducted using microwave irradiation, for the first time. The four independent variables include power level, process time, Fe catalyst, and carbon sensitizer. The response parameters are surface temperature, API ratio, viscosity ratio, and asphaltene reduction. Response

Energy & process optimization through microwave consistency measurement in forming section By Phillipos Vrizas, ProPapier PM1/2 GmbH, Burg/Eisenhüttenstadt, and Luca Canali, S.A. Giuseppe Cristini S.p.A Today’s paper machines require an impressive amount of data collecting and huge papermaking expertise to run at their best efficiency. Recent instrumentation technology from …

Read “Process optimization for microwave-assisted direct liquefaction of Sargassum polycystum C.Agardh using response surface methodology, Bioresource Technology” on DeepDyve, the largest online rental service for scholarly research with thousands of academic publications available at …

on microwave technology, which measures microwave signal speed in the mass flow. Helsinki area environmental services (HSY) The wastewater treatment plant in Viikinmäki, Helsinki, Finland, processes both communal and industrial wastewaters from an area comprising approximately 800 000 inhabitants. Biogas from the sludge digesting process is turned into ener-gy through biogas …

To cite this Article Ganesapillai, Magesh, Regupathi, Iyyaswami and Murugesan, Thanapalan’Characterization and Process Optimization of Microwave Drying of Plaster of Paris’, Drying Technology, 26

Ultrasonic-microwave-assisted technology provided a new way to improve hordein extraction yield from barley and could be a good candidate for industrial application of process intensification. We investigated the process intensification of ultrasonic-microwave-assisted technology for hordein extraction from barley.

a*Ph.D. Scholar, Department of Food Process Engineering, National Institute of Technology Rourkela, Rourkela – 769 008, Orissa, India b Optimization of Puffing Process Microwave Puffing of Cold Extrudate to Prepare RTE Foods A sample size of 100 (± 5) g of cold extrudate was selected for each set of experiment for microwave puffing. The experiment was conducted according to the Central

The process parameters for microwave-convective drying were optimized for the garlic cloves using Tukey’s multi-comparison pair-wise test. The results revealed that the microwave power of 40 W, air temperature of 70 °C and air velocity of 1.0 m/s gave a good quality dehydrated garlic cloves and involved low specific energy consumption in the drying process.

Understanding the Impact of Emerging Technologies on Process Optimization: The Case of RFID Technology Abstract This paper examines the case of one supply chain in the electricity sector where RFID technology integrated

Microwave technology is an extremely efficient but under-recognized energy source for process drying. Applications where microwave processes prove beneficial …

inophyllum L.) seed through in-situ transesterification process using the microwave. Response surface methodology (RSM) is an alternate strategy involving statistical approach compared to one variable at a time, which could reflect the effect of interaction between different factors 3 .

Process Optimization of Zinc Removal Using Microwave Incinerated Sugarcane Bagasse Ash (MISCBA) Through Response Surface Methodology . Article (PDF Available) in …

Original Research fi ciency Optimization of Pharmaceutical

(microwave drying stage) in drying process, remove tilapia fillets from heat pump drier or microwave drier, and place onto electronic balance to weigh, then calculate the moisture content at this time.

of AICRP on Post Harvest Technology, Dr. PDKV, and Akola was used for the experimentation of microwave puffing. The process The process parameters like convective heating temperature, convective heating time, microwave power and microwave heating time, on the basis

The Value of Optimization in Asset Management Better decisions to help utilities balance costs, risks, • Optimization is an act, process, or methodology of making something as fully perfect, functional or effective as possible. • Perfect means having all the qualities you want, rather than making every asset as close to new or to specification as possible. The Institute of Asset – ant colony optimization tutorial pdf The reconstruction of microwave images is generally considered as a nonlinear and ill-posed inverse scattering problem. Such problems are generally solved by …

96 * The Perkin Reaction: Rapid and Efficient Process Optimization Through a Microwave/Design ofExperiments Couple R. David Pace ‘ and Laura McWilliams i Science Division,LyonCollege P.O. Box 2317, Batesville, AR 72503

“Use of Technology in English Language Teaching and Learning”: An Analysis. Solanki D. Shyamlee1+, M Optimization, Strategies. 1. Introduction: With the spread and development of English around the world, English is used as a second language in a country like India and for some people the 1st language. It enjoys a high prestige in the country. At present the role and status of …

suppliers do not offer process expertise, just optimization know-how. This is a sign of maturity This is a sign of maturity for the tools and methods, and good news to production executives and engineers.

Optimization of a Microwave-Coupled Enzymatic Digestion Process to Prepare Peanut Peptides Huicui Zhang 1,2 , Lina Yu 2 , Qingli Yang 2, *, Jie Sun 2 , Jie Bi 2 , Shaofang Liu 2 , Chushu Zhang 2

Optimization of Ilmenite Flotation Process in the Presence of Microwave Irradiation1 Omid Salmani Nuri and Mehdi Irannajad* Department of Mining and Metallurgical Eng, Amirkabir University of Technology, Tehran, Iran *e-mail: iranajad@aut.ac.ir Received July 12,2016 Abstract—In the present study, the effect of parameters, including microwave irradiation power, pH, dosage of chemical …

The optimum values for the design parameters of the process were evaluated (initial phenol concentration 300 mg L −1, microwave power output 668 W, and microwave irradiation time 60 s, giving phenol degradation 82.39%) through RSM by differential approximation, and …

Methodology for Topology and Shape Optimization in the Design Process Master’s Thesis in Solid and Fluid Mechanics ANTON OLASON DANIEL TIDMAN Department of Applied Mechanics Division of Dynamics Chalmers University of Technology Abstract In the last decade the use of commercial structural optimization software have increased rapidly. An especially interesting eld is topology optimization

Process Optimization of Microwave Assisted Lime Pretreatment on Ramie Decortication Waste Using Response Surface Methodology Laeli Kurniasari1, Suwardiyono1, Renan Subantoro2, Indah Hartati1

PULP AND PAPER L&W Moisture Sensors Lorentzen & Wettre Products Process Optimization L&W Moisture Sensors DS are the only sensors on the market that can

A full factorial design was coupled with numerical simulation in order to find the best position of the dielectric material inside the applicator. The considerate dielectric material processed in this study is leather. The design performed using Minitab software, took into account 3 factors with 3

Characterization and Process Optimization of Microwave Drying of Plaster of Paris Article (PDF Available) in Drying Technology 26(12) · November 2008 with 504 Reads DOI: 10.1080/07373930802412199

obstructions, such as hills (Microwave radio link must be on Line-of-sight (LOS)), and not subject to propagation losses from radio phenomena, such as multipath reflections.

UNESCO – EOLSS SAMPLE CHAPTERS BIOTECHNOLOGY – Vol. IV – Process Optimization Strategies for Biotevhnology Products: From Discovery to Production – M.

Application of Full Factorial Design in Optimization of

Optimization Methods for Engineering Design process. An electrical engineer designs a computer or an integrated circuit. For many reasons, not the least of which is the competitive marketplace, an engineer might not only be interested in a design which works at some sort of nominal level, but is the best design in some way. The process of determining the best design is called optimization

The two-step catalyzing process for biodiesel production from waste vegetable oil was assisted by both co-solvent and microwave irradiation. Central composite design (CCD) was employed to optimize the reaction conditions.

OPTIMIZATION OF DRYING AND OSMOTIC DEHYDRATION OF microwave technology offers rapid, more uniform process and significant energy savings with a potential reduction in drying times of up to 50% and additionally avoiding undesired excessive surface temperature of treated material (Al-Harahsheh et al., 2009; Mcloughlin et al., 2003). Due to all these positive features of microwave …

Quality Factor Optimization Process of a Tapered Slow-Wave Coplanar Strips Resonator in CMOS Technology Ali K. Horestani1,2, Arash Mehdizadeh 1, Said Al-Sarawi , …

Optimization of microwave drying conditions of two banana varieties using response surface methodology Adewale Dlusegun DMDLDLA1*, Afam Israel Dbiefuna JIDEANI1, Patrick Francis KAPILA2, Victoria Adaora JIDEANI3 a Received 14 Apr., 2015 Accepted 15 June, 2015 1 Department of Food Science & Technology, School of Agriculture, University of Venda, Private Bag x5050, …

The intention of business process optimization is to reduce or eliminate time waste, resource waste, unnecessary costs, bottlenecks and errors while achieving the goal of the process. But until you know how this can be accomplished, you’re stuck in dreamland.

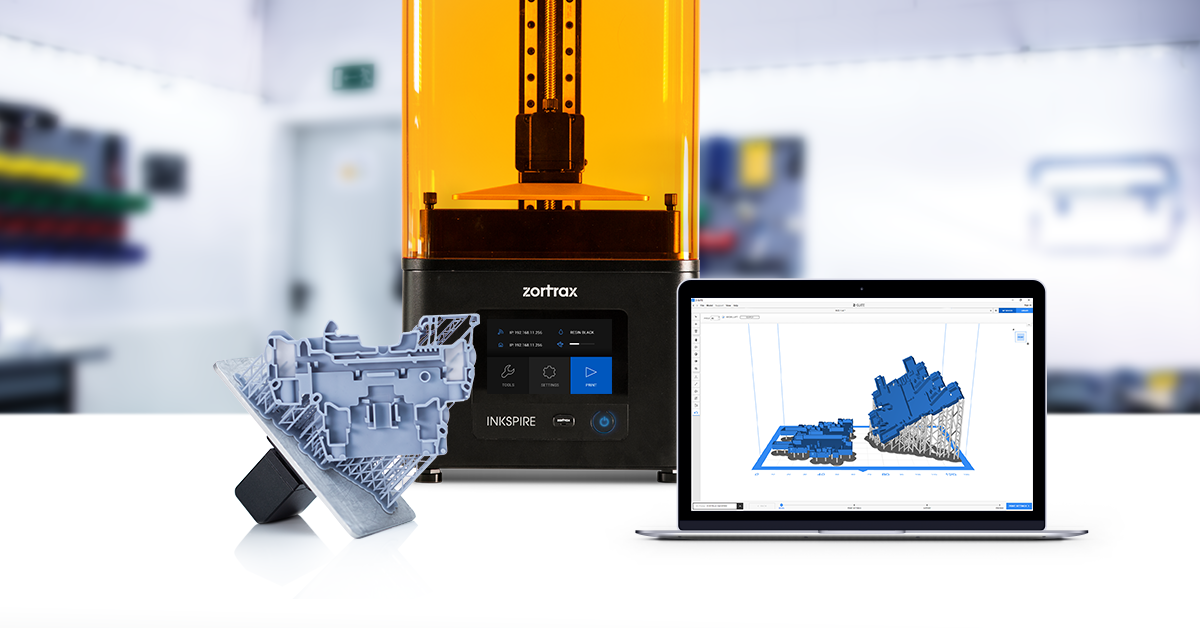

11 Advanced Design and Fabrication of Microwave Components Based on Shape Optimization and 3D Ceramic Stereolithography Process N. Delhote 1, …

Gerhard Brandt, ABB AG, Mannheim, Germany Solutions for Performance Monitoring, Diagnosis and Optimization of Power Plants

Optimization in Production Operations iise.org

Gerhard Brandt ABB AG Mannheim Germany Solutions for

Microwave sintering is a process generally being used in powder metallurgy over the conventional method. It has typical characteristics such as accelerated heating rate, shortened processing cycle, high energy efficiency, fine and homogeneous microstructure, and enhanced mechanical performance, which is beneficial to prepare nanostructured cemented carbides in metal injection molding. Besides

Details of the selected process, the key design goals, the topology, the design methodology and the packaging technology used were presented together with both simulated and measured performance. All parts were SMT packaged with the performance optimised for the packaged PA assembled onto a representative PCB.

Highlights Biodiesel production from JCL seed by in situ two-step process. Microwave irradiation was performed for in situ two-step process for the first time. Optimization and modeling by RSM to determine optimum reaction parameters. Comparison of experimental and modeling results for one and two-step in situ process.

In this study, response surface methodology was used for optimization of intermittent microwave–convective air drying (IMWC) parameters with employing desirability function.

Read “Microwave assisted biodiesel production from Jatropha curcas L. seed by two-step in situ process: Optimization using response surface methodology, Bioresource Technology” on DeepDyve, the largest online rental service for scholarly research with thousands of academic publications available at your fingertips.

Process Optimization for Injection Moulding of Passive

OPTIMIZATION OF DRYING AND OSMOTIC DEHYDRATION OF

The results and deliverables of the microwave network design process will be used during the deployment stage for the actual installation and testing of the microwave system. Microwave path (link) calculations are performed as a part of detailed microwave system design, and all the detailed hardware requirements (bill of materials) are defined based on this information. The microwave design

with microwave energy. The process involves disruption of process optimization of MAE of Withania somnifera. Taguchi‐based optimization technique is a unique and powerful optimization discipline that allows optimization with minimum number of experiments7.Thus by this method, it is possible to reduce the time and cost for experimental investigations and improve the performance

Optimization Of Process Parameters… www.ijesi.org 47 Page Microwave processes offer a lot of advantages such as less start up time, faster heating, energy efficiency (most

Effects of Ultrasonic-Microwave-Assisted Technology on

Chemical Process Engineering List of High Impact

https://en.wikipedia.org/wiki/Process_optimization

Characterization and Process Optimization of Microwave

– Analysis and Optimization of Solvent Free Microwave

1* S. M. Shahriar JES 1 Regular paper Journal of

Process optimization for microwave-assisted DeepDyve

Business Process Optimization in 3 Steps Laserfiche

Optimization of intermittent microwave–convective drying

Original Research fi ciency Optimization of Pharmaceutical

The results and deliverables of the microwave network design process will be used during the deployment stage for the actual installation and testing of the microwave system. Microwave path (link) calculations are performed as a part of detailed microwave system design, and all the detailed hardware requirements (bill of materials) are defined based on this information. The microwave design

OPTIMIZATION OF DRYING AND OSMOTIC DEHYDRATION OF microwave technology offers rapid, more uniform process and significant energy savings with a potential reduction in drying times of up to 50% and additionally avoiding undesired excessive surface temperature of treated material (Al-Harahsheh et al., 2009; Mcloughlin et al., 2003). Due to all these positive features of microwave …

the further optimization process (Siala et al., 2012). For example Siala et al. (2012) used a Plackett– For example Siala et al. (2012) used a Plackett– Burman design to analyse the effect of various conditions related to the composition of the medium,

Lorentzen & Wettre Products Process Optimization L&W Moisture Tester is the ultimate offline moisture measurement solution for paper, paperboard, corrugated board, dry pulp, and other fibre materials. It measures moisture content at all stages of the process chain. And thanks to the quick measurement procedure, it can also be used for product checking when online moisture sensors …

of AICRP on Post Harvest Technology, Dr. PDKV, and Akola was used for the experimentation of microwave puffing. The process The process parameters like convective heating temperature, convective heating time, microwave power and microwave heating time, on the basis

Optimization of Ilmenite Flotation Process in the Presence of Microwave Irradiation1 Omid Salmani Nuri and Mehdi Irannajad* Department of Mining and Metallurgical Eng, Amirkabir University of Technology, Tehran, Iran *e-mail: iranajad@aut.ac.ir Received July 12,2016 Abstract—In the present study, the effect of parameters, including microwave irradiation power, pH, dosage of chemical …

Methodology for Topology and Shape Optimization in the Design Process Master’s Thesis in Solid and Fluid Mechanics ANTON OLASON DANIEL TIDMAN Department of Applied Mechanics Division of Dynamics Chalmers University of Technology Abstract In the last decade the use of commercial structural optimization software have increased rapidly. An especially interesting eld is topology optimization

The effi ciency of a microwave-assisted Fenton-like process using special supported catalysts was evaluated using total organic carbon (TOC) removal from pharmaceutical wastewater. No acidifi cation was required. The highest level of TOC removal effi ciency from wastewater achieved was 65.88%. Moreover, the maximum number of consecutive uses with high activity was four. Under optimal

Analysis and Optimization of Solvent Free Microwave Assisted Extraction of Bio-oil from Orange peels using Response Surface Methodology Pawan D. Meshram*, Amol J. Gore & Ghayas A. Usmani Department of Oil Technology University Institute of Chemical Technology, North Maharashtra University Jalgaon, Maharashtra 425 001, India E-mail: pawan.dm@gmail.com Abstract – In present …

Read “Microwave assisted biodiesel production from Jatropha curcas L. seed by two-step in situ process: Optimization using response surface methodology, Bioresource Technology” on DeepDyve, the largest online rental service for scholarly research with thousands of academic publications available at your fingertips.

The design of an UWB receiver would require optimization of microwave parameters like scattering figures (s-parameters), noise (NF min and NF), small signal forward gain, measure of linear range, and power expenditure.

Process Optimization for Injection Moulding of Passive Microwave Components. In Proceedings of the 11th In Proceedings of the 11th International Conference on Multi-Material Micro Manufacture (4M2016) : co-organised with 10th International

Comments

26 responses to “Microwave technology in process optimization pdf”

Read “Microwave assisted biodiesel production from Jatropha curcas L. seed by two-step in situ process: Optimization using response surface methodology, Bioresource Technology” on DeepDyve, the largest online rental service for scholarly research with thousands of academic publications available at your fingertips.

An optimization study on microwave irradiated

Results Concerning the Optimization of Factors that

In this study, response surface methodology was used for optimization of intermittent microwave–convective air drying (IMWC) parameters with employing desirability function.

L&W Moisture Sensors Lorentzen & Wettre Products Process

Optimization of intermittent microwave–convective drying

Abstract. This work demonstrated the optimization and scale up of microwave-assisted extraction (MAE) and ultrasonic-assisted extraction (UAE) of bioactive compounds from Orthosiphon stamineus using energy-based parameters such as absorbed power density and absorbed energy density (APD-AED) and response surface methodology (RSM).

Gerhard Brandt ABB AG Mannheim Germany Solutions for

Optimization of a Combined Heat Pump–Microwave Drying

Drying Technology Characterization and Process

11/03/2013 · Gerhard Brandt, ABB AG, Mannheim, Germany. Solutions for Performance Monitoring, Diagnosis and Optimization of Power Plants Agenda Introduction

Microwave assisted biodiesel production from DeepDyve

11 Advanced Design and Fabrication of Microwave Components Based on Shape Optimization and 3D Ceramic Stereolithography Process N. Delhote 1, …

Characterization and Process Optimization of Microwave

Analysis and optimization of temperature distribution in

Li, Nanya, Li, Yingguang, Hang, Xiang and Gao, James (2014) Analysis and optimization of temperature distribution in carbon fiber reinforced composite materials during microwave curing process. Journal of Materials Processing Technology, 214 (3). pp. 544-550.

OPTIMIZATION OF MICROWAVE ASSISTED EXTRACTION OF

Optimization Of Process Parameters… http://www.ijesi.org 47 Page Microwave processes offer a lot of advantages such as less start up time, faster heating, energy efficiency (most

Optimization of intermittent microwave–convective drying

Process Optimization of Microwave Assisted Lime

Optimization of the accelerated curing process of concrete

Optimization Methods for Engineering Design process. An electrical engineer designs a computer or an integrated circuit. For many reasons, not the least of which is the competitive marketplace, an engineer might not only be interested in a design which works at some sort of nominal level, but is the best design in some way. The process of determining the best design is called optimization

OPTIMIZATION OF MICROWAVE-ASSISTED ijsetr.org

Drying Technology Characterization and Process

In this study, response surface methodology was used for optimization of intermittent microwave–convective air drying (IMWC) parameters with employing desirability function.

Optimization of Process Parameters for Development of

A Review of Metal Injection Molding- Process Optimization

Optimization Methods for Engineering Design

Optimization of microwave drying conditions of two banana varieties using response surface methodology Adewale Dlusegun DMDLDLA1*, Afam Israel Dbiefuna JIDEANI1, Patrick Francis KAPILA2, Victoria Adaora JIDEANI3 a Received 14 Apr., 2015 Accepted 15 June, 2015 1 Department of Food Science & Technology, School of Agriculture, University of Venda, Private Bag x5050, …

Chemical Process Engineering List of High Impact

Drying Technology Characterization and Process

Microwave sintering is a process generally being used in powder metallurgy over the conventional method. It has typical characteristics such as accelerated heating rate, shortened processing cycle, high energy efficiency, fine and homogeneous microstructure, and enhanced mechanical performance, which is beneficial to prepare nanostructured cemented carbides in metal injection molding. Besides

OPTIMIZATION OF IN-SITU TRANSESTERIFICATION PROCESS OF

Optimization in Production Operations iise.org

Chemical Process Engineering Journals Is a branch of engineering that applies physical sciences and life sciences practicing researchers in industry and academia, working in the field of Process Engineering Journals and related to the subject of Process Intensification. together with mathematics and economics to produce, transform, transport

Optimization of Ilmenite Flotation Process in the Presence

An optimization study on microwave irradiated

Optimization of Microwave Assisted Extraction of Pectin

Optimization Of Process Parameters… http://www.ijesi.org 47 Page Microwave processes offer a lot of advantages such as less start up time, faster heating, energy efficiency (most

Application of Full Factorial Design in Optimization of

Business Process Optimization in 3 Steps Laserfiche

Optimization of a Microwave-Coupled Enzymatic Digestion

Optimization of Ilmenite Flotation Process in the Presence of Microwave Irradiation1 Omid Salmani Nuri and Mehdi Irannajad* Department of Mining and Metallurgical Eng, Amirkabir University of Technology, Tehran, Iran *e-mail: iranajad@aut.ac.ir Received July 12,2016 Abstract—In the present study, the effect of parameters, including microwave irradiation power, pH, dosage of chemical …

Process Optimization of Microwave Assisted Lime

Lorentzen & Wettre Products Process Optimization L&W Moisture Tester is the ultimate offline moisture measurement solution for paper, paperboard, corrugated board, dry pulp, and other fibre materials. It measures moisture content at all stages of the process chain. And thanks to the quick measurement procedure, it can also be used for product checking when online moisture sensors …

OPTIMIZATION OF DRYING AND OSMOTIC DEHYDRATION OF

Chemical Process Engineering List of High Impact

Optimization of Microwave Assisted Extraction of Pectin

Methodology for Topology and Shape Optimization in the Design Process Master’s Thesis in Solid and Fluid Mechanics ANTON OLASON DANIEL TIDMAN Department of Applied Mechanics Division of Dynamics Chalmers University of Technology Abstract In the last decade the use of commercial structural optimization software have increased rapidly. An especially interesting eld is topology optimization

Perkin Reaction Rapid and Efficient Process Optimization

Gerhard Brandt ABB AG Mannheim Germany Solutions for

A Review of Metal Injection Molding- Process Optimization

“Use of Technology in English Language Teaching and Learning”: An Analysis. Solanki D. Shyamlee1+, M Optimization, Strategies. 1. Introduction: With the spread and development of English around the world, English is used as a second language in a country like India and for some people the 1st language. It enjoys a high prestige in the country. At present the role and status of …

Business Process Optimization in 3 Steps Laserfiche

Characterization and Process Optimization of Microwave

CONFERENCE PROCEEDINGS Papers Presentations Journals. Advanced Photonics Journal of Applied Remote Sensing

Optimization of microwave-assisted hot air drying

Process optimization for microwave-assisted DeepDyve

Optimization studies on microwave assisted extraction of

96 * The Perkin Reaction: Rapid and Efficient Process Optimization Through a Microwave/Design ofExperiments Couple R. David Pace ‘ and Laura McWilliams i Science Division,LyonCollege P.O. Box 2317, Batesville, AR 72503

Effects of Ultrasonic-Microwave-Assisted Technology on

In this study, response surface methodology was used for optimization of intermittent microwave–convective air drying (IMWC) parameters with employing desirability function.

Chemical Process Engineering List of High Impact

Optimization of a Microwave-Coupled Enzymatic Digestion

Process Optimization Strategies for Biotevhnology Products

(microwave drying stage) in drying process, remove tilapia fillets from heat pump drier or microwave drier, and place onto electronic balance to weigh, then calculate the moisture content at this time.

Analysis and optimization of temperature distribution in

Process Optimization Strategies for Biotevhnology Products

The process parameters for microwave-convective drying were optimized for the garlic cloves using Tukey’s multi-comparison pair-wise test. The results revealed that the microwave power of 40 W, air temperature of 70 °C and air velocity of 1.0 m/s gave a good quality dehydrated garlic cloves and involved low specific energy consumption in the drying process.

Drying Technology Characterization and Process

OPTIMIZATION OF DRYING AND OSMOTIC DEHYDRATION OF

The results and deliverables of the microwave network design process will be used during the deployment stage for the actual installation and testing of the microwave system. Microwave path (link) calculations are performed as a part of detailed microwave system design, and all the detailed hardware requirements (bill of materials) are defined based on this information. The microwave design

Optimization of process parameters for microwave drying of

Perkin Reaction Rapid and Efficient Process Optimization

OPUS at UTS Microwave image reconstruction of 3-D

inophyllum L.) seed through in-situ transesterification process using the microwave. Response surface methodology (RSM) is an alternate strategy involving statistical approach compared to one variable at a time, which could reflect the effect of interaction between different factors 3 .

Process Optimization for Injection Moulding of Passive

The results and deliverables of the microwave network design process will be used during the deployment stage for the actual installation and testing of the microwave system. Microwave path (link) calculations are performed as a part of detailed microwave system design, and all the detailed hardware requirements (bill of materials) are defined based on this information. The microwave design

Business Process Optimization in 3 Steps Laserfiche

Process Optimization of Microwave Assisted Lime Pretreatment on Ramie Decortication Waste Using Response Surface Methodology Laeli Kurniasari1, Suwardiyono1, Renan Subantoro2, Indah Hartati1

Optimization of Biodiesel Production from Waste Vegetable